INNOVATIONS POWER

ABOUT OURSELVES

WORKSHOP EQUIPMENT AND CONTRACT MANUFACTURING "MADE IN GERMANY"

In everything we do, we always bear our responsibility for people and nature in mind.

At our Frickenhausen location, highly motivated employees give their best every day in the areas of engineering, prototyping, sheet metal production and assembly. We not only use our core competencies in laser cutting, edging and welding for our own equipment and tool construction, but also make them available to you cost-effectively as contract services. We develop tailor-made solutions, realise prototypes and manufacture reliably according to your specifications keeping your requirements and workflows in mind. Our solutions are as unique as the tasks you set us.

Safe products with a high degree of user-friendliness and fair cooperation form the basis for healthy growth and sustainable business relationships which ensure our competitiveness. That is why we attach special importance to a close and trusting relationship with our customers, suppliers and employees.

OUR KNOW-HOW

INNOVATIVE SOLUTIONS IN OUTSTANDING QUALITY

All services are provided in Germany. That makes us good, fast and flexible. We purchase components exclusively from German or European suppliers with whom we have long-term cooperation. All our products are certified in accordance with DIN EN ISO 9001:2015.

With a far-sighted view of tomorrow's markets, many years of know-how and a passion for innovative solutions, we pay attention to the perfect interplay between the latest technology, careful workmanship and sustainable materials. We ensure the high reliability and excellent quality of our products and services by constantly developing our products and work processes. Our ambition to become better and better is our drive - and the benchmark for our quality management system, which we address every day in the "Continuous Improvement Process" (CIP).

OUTSTANDING PRODUCTS

CREATIVE POWER AT THE HIGHEST LEVEL

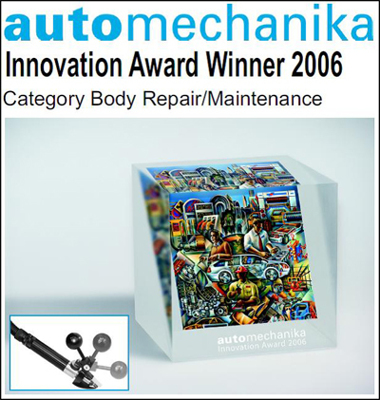

Every day we work with a high level of innovation to develop devices which create added value for you and your work processes. The results are products "at a genius level" - new developments which make us proud and have been awarded prizes in innovation competitions.

All workshop equipment at GL is largely manufactured in Germany. We obtain the majority of our vendor parts from German manufacturers or from other EU countries. In rare cases we fall back on international manufacturers. The lion's share of the added value is always created in Frickenhausen. Our devices are assembled and subjected to quality control by us or our local assembly companies. This is why GL articles truly earn the title "Made in Germany".

OUR HISTORY

MILESTONES WHICH MADE HISTORY.

2020

GL is making good use of their time during the coronavirus crisis by developing the new hygiene product line. The development of disinfection towers and panels, all in the usual high quality associated with GL, is opening up new customer target groups in addition to our regular customers in the automotive and mechanical engineering industries. Hygiene will continue to play a major role even after corona as hygiene standards in workshops and companies improve. That is why GL is already developing additional products for the new product line, such as hygiene columns with a foot pedal, mobile disinfection stations for event organisers, and care disinfectants, all under its own label.

2019

Innovative solutions, in response to the latest developments in the automotive industry, have made GL an absolute premium partner for manufacturers and wholesalers. The new SDS 5 shock absorber flushing device continues the long tradition of successful innovations from GL.

2018

With the implementation of the 2. In the second construction phase, GL is using the entire area available for building on the company premises in Frickenhausen. 380 square metres of additional assembly and storage space are being created, which is urgently needed to enable the 50 employees who now work there to work to their full potential.

2017

If you want to become continuously better, you need the best tools. The investment in a Trumpf TruLaser 3030 laser cutting machine of the newest generation was another milestone for the company to become faster, better and more cost-effective. Consistency along the value-added chain – parallel to the laser machine, a new Trumpf TruBend press brake was added to the machine park to reach a new level in the "edging" area as well.

2015

The Frickenhausen location was expanded by 1,500 square metres of usable space. The assembly of workshop equipment (brake maintenance, AdBlue filling equipment, wheel mounting aids, EasyLift, etc.) is now housed in the new production hall. In addition, additional meeting and recreation rooms were built together with new sanitary facilities. The new building was completed during ongoing production and inaugurated with employees and customers in September 2015.

2014

We plan to expand the production capacity at our Frickenhausen location by a further 2000 square metres. As well as this, jobs will be created and the core workforce will be increased from 45 to approx. 50.

2013

GL is established as the leading manufacturer of automotive repair equipment in Germany. In the field of sheet metal manufacturing, GL remains a service provider for well-known customers in a variety of industries.

The company is continually growing and the business area of automotive repair technology is developing in a dynamic way. The product spectrum is being constantly expanded, which is also increasing our customer base.

2012

To present the sustainable success of the last few years visually, a totally new corporate design is developed. Our first big presentation with our new appearance is the leading industry trade fair automechanika in Frankfurt am Main.

2011

Adolf Henzler transfers the company in full to his sons Holger und Thomas. He remains in the position of head of innovation, enabling the company to retain his creative power for research and development.

2008

Competition in Baden-Württemberg. Then-minister-president Oettinger appraises innovations, in this case our laser-welding seam milling cutter

2006

Distinction in Innovation prize of the province of Baden-Württemberg, Rudolf-Eberle-Prize. In the picture: President of the Government Schmalzl, Minister for Economic Affairs Pfister, FDP

2006

Winner of the automechanika Innovation Award: laser-welding seam milling cutter

2006

GL GmbH buys the premises in Frickenhausen. The company thereby demonstrates its intention of staying in Germany on a long-term basis. The buildings and machinery plant are modernised.

2005

The founder Heinz Grünwasser goes into retirement. His shares are taken over by Holger and Thomas Henzler, the sons of his co-owner Adolf Henzler. Simultaneously with this transfer from one generation to another, GL becomes a family business.

2002

The company continues to grow. The new location in 23 – 25 Nürtinger Street in Frickenhausen is leased and occupied. The company’s name is changed to “GL GmbH Metall- und Werkstattechnik”.

First appearance at the leading industry trade show "automechanika" in Frankfurt/Main.

2000

The business unit “Werkstattechnik” (automotive repair technology) is added. Brake maintenance equipment is developed, manufactured and marketed by us for the first time.

1993

Adolf Henzler enters the company as the new co-owner, with a share of 50%. The company is renamed to GL Laserstrahltechnik (Laser Beam Technology) GmbH. The manufacturing depth is gradually increased to include folding and welding. The company continually grows as a subcontractor for well-known clients in the machine construction and automotive industries.

1991

The company is founded under the name G+R Laserstrahltechnik GmbH.

Steel sheet metal is processed with laser cutting machines, to create sheet metal parts and sheet metal assemblies, as commissioned by our clients.